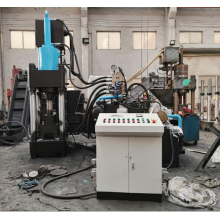

Ecohydraulic briquette machines can briquette a multitude of materials including aluminum, brass, bronze, cast iron, copper, magnesium, steel, titanium, zinc, etc. The dense briquettes that are produced are less susceptible to corrosion and an attractive proposition to foundries. The press has advantages as follows: heavy reduction of volume, reducing storage and transportation costs, recycling of expensive cooling lubricants, recipients often pay a better price for loosing millings, minimal burn-off and increased glaze recovery.

1. Application and features for Vertical Red Copper Brass Chippings Briquette Making Machine

We recommend you a fully-automatic metal briquetting line, with conveyor, bunker, elevator, etc. Our Y83 Vertical Briquetting Press has advantages as follows:

1) suitable for tiny metal scraps| model | Y83-360 |

| nominal force | 3600kn |

| briquette diameter | D100 (customized) |

| briquette density | ≥ 5.0t/m³ |

| briquette weight | 3~4kg |

| productivity | 3~4block/min |

| output in one shift | 4~5t/8h |

| total power | 30kw |

| machine weight | about 7ton |

| overall dimension | host machine: 780*2150*4000mm oil tank: 1350*1400*1160mm |

Product Categories : Briquette Machine > Copper Briquette Machine

Horizontal Copper Chip Blocker Block Moulding Machine

Contact Now

Contact Now

Standard Duty Metal Chip Briquette Press Machine

Contact Now

Contact Now

Hydraulic Metal Chip Processing Briquetting Press Machine

Contact Now

Contact Now

Y83 Series Scrap Metal Aluminum Chips Briquetting Press

Contact Now

Contact Now

Iron Turnings Shavings Swarf Chips Briquette Machine

Contact Now

Contact Now

High Capacity Sponge Iron Scrap Metal Briquette Machine

Contact Now

Contact Now

Hydraulic Vertical Aluminium Chips Briquette Making Machine

Contact Now

Contact Now

Scrap Metal Aluminium Briquette Presses Cake Press

Contact Now

Contact Now